Pre-Fab Ground Water Recharge

Pre-Fab Ground Water Recharge

About

Our Pre-Fab Ground Water Recharge solution utilizes injection wells to recharge the groundwater, providing an assured water supply for domestic, agricultural, and industrial purposes. Our technology is sustainable, cost-effective, and easy to maintain, making it an ideal solution for both urban and rural areas.

- Rainwater recharge using injection wells

- Eco-friendly and gravity-based technology

- Benefits include an assured water supply and a reduced carbon footprint.

Benefits

- Secure water supply for all, rural and urban

- Bridge the gap during peak summer months

- Hygienic and safe drinking water

- Reduce bore well hardness, salinity and TDS

- Check seawater ingression in coastal areas

- Enhance limited groundwater resources

- Combat global warming by recharging groundwater

- Lower carbon footprints significantly

- Prevent water logging in low-lying areas

- Sustainable solution for low-yield bore wells and springs

Benefits

- Secure water supply for all, rural and urban

- Bridge the gap during peak summer months

- Hygienic and safe drinking water

- Reduce bore well hardness, salinity and TDS

- Check seawater ingression in coastal areas

- Enhance limited groundwater resources

- Combat global warming by recharging groundwater

- Lower carbon footprints significantly

- Prevent water logging in low-lying areas

- Sustainable solution for low-yield bore wells and springs

Salient Feature of The Technology

- V wire technology: Eco-friendly and sustainable water recharge solution.

- Gravitational recharge: Natural and effective way to replenish groundwater.

- No moving parts: Minimal maintenance and maximum reliability.

- Sustainable solution: 20-year lifespan and recyclable materials.

- Efficient technology: Electrical sounding for precise well location.

- Cost-effective: Low maintenance and high-performance technology.

Salient Feature of The Technology

- VES for Injection well identification: Accurate and efficient groundwater mapping.

- V wire material: Long-lasting and environmentally conscious choice.

- Easy maintenance: Simple de-silting and filtration media replacement.

- Earth-friendly option: Insulated groundwater recharge reduces carbon footprint.

- Cost-effective: Low maintenance and high-performance technology.

Over 5,000 successful installations of the V-wire injection well technology across India, in both public and private sectors, including various Government sponsored projects under National Rural drinking water supply programs, Suvarna Jala and also through various Zilla Panchayaths, Gram Panchayaths, Municipalities, Nirmithi Kendra’s, Urban water supply Boards, Rural Water Supply Boards, Ground Water Development Agencies, Konkan Railways, Apartments Commercial buildings, School Buildings.

Industries and Corporate sector like Infosys, LANCO highway Projects, SKF, VKC, UB distilleries and agricultural sectors.

Just 12.5 mm of rain can yield an astonishing 50,000 litres of water per acre, with a minimum of 30,000 litres being rechargeable into the groundwater source. This amounts to 2.1 million litres per injection well during an average 70-day rainfall spread. Coastal areas with higher rainfall of 3000 to 3500 mm per year can inject a minimum of 50,000 to 1,00,000 liters per day, with a potential percolation of 4.5 million litres per well spread over 90 days annually.

Just 12.5 mm of rain can yield an astonishing 50,000 litres of water per acre, with a minimum of 30,000 litres being rechargeable into the groundwater source. This amounts to 2.1 million litres per injection well during an average 70-day rainfall spread. Coastal areas with higher rainfall of 3000 to 3500 mm per year can inject a minimum of 50,000 to 1,00,000 liters per day, with a potential percolation of 4.5 million litres per well spread over 90 days annually.• The technology has garnered widespread acceptance and adoption among farmers and households through public-private initiatives, including governmental agencies and an extensive dealer network.

• Over 5000 bore wells in rural and urban areas, both public and private, have been successfully recharged, bringing an abundance of water to previously parched farmland.

Over 5,000 successful installations of the V-wire injection well technology across India, in both public and private sectors, including various Government sponsored projects under National Rural drinking water supply programs, Suvarna Jala and also through various Zilla Panchayaths, Gram Panchayaths, Municipalities, Nirmithi Kendra’s, Urban water supply Boards, Rural Water Supply Boards, Ground Water Development Agencies, Konkan Railways, Apartments Commercial buildings, School Buildings.

Industries and Corporate sector like Infosys, LANCO highway Projects, SKF, VKC, UB distilleries and agricultural sectors.

Just 12.5 mm of rain can yield an astonishing 50,000 litres of water per acre, with a minimum of 30,000 litres being rechargeable into the groundwater source. This amounts to 2.1 million litres per injection well during an average 70-day rainfall spread. Coastal areas with higher rainfall of 3000 to 3500 mm per year can inject a minimum of 50,000 litres per day, with a potential percolation of 4.5 million litres per well spread over 90 days annually.

• The technology has garnered widespread acceptance and adoption among farmers and households through public-private initiatives, including governmental agencies and an extensive dealer network.

• Over 5000 bore wells in rural and urban areas, both public and private, have been successfully recharged, bringing an abundance of water to previously parched farmland.

V-Wire Type Vs Conventional Type

V-Wire Type

1- The specialized silt trap in ‘V’ wire technology uses a non-clogging SS 304 food-graded material with a horizontally placed V wire screen filter to ensure only clean water passes through to the injection well.

2- The depth of the recharge point in FLRWH ‘V’ wire technology varies from 20 to 60 meters, allowing for self-purification of the water, and reducing salinity, hardness, and fluoride contents.

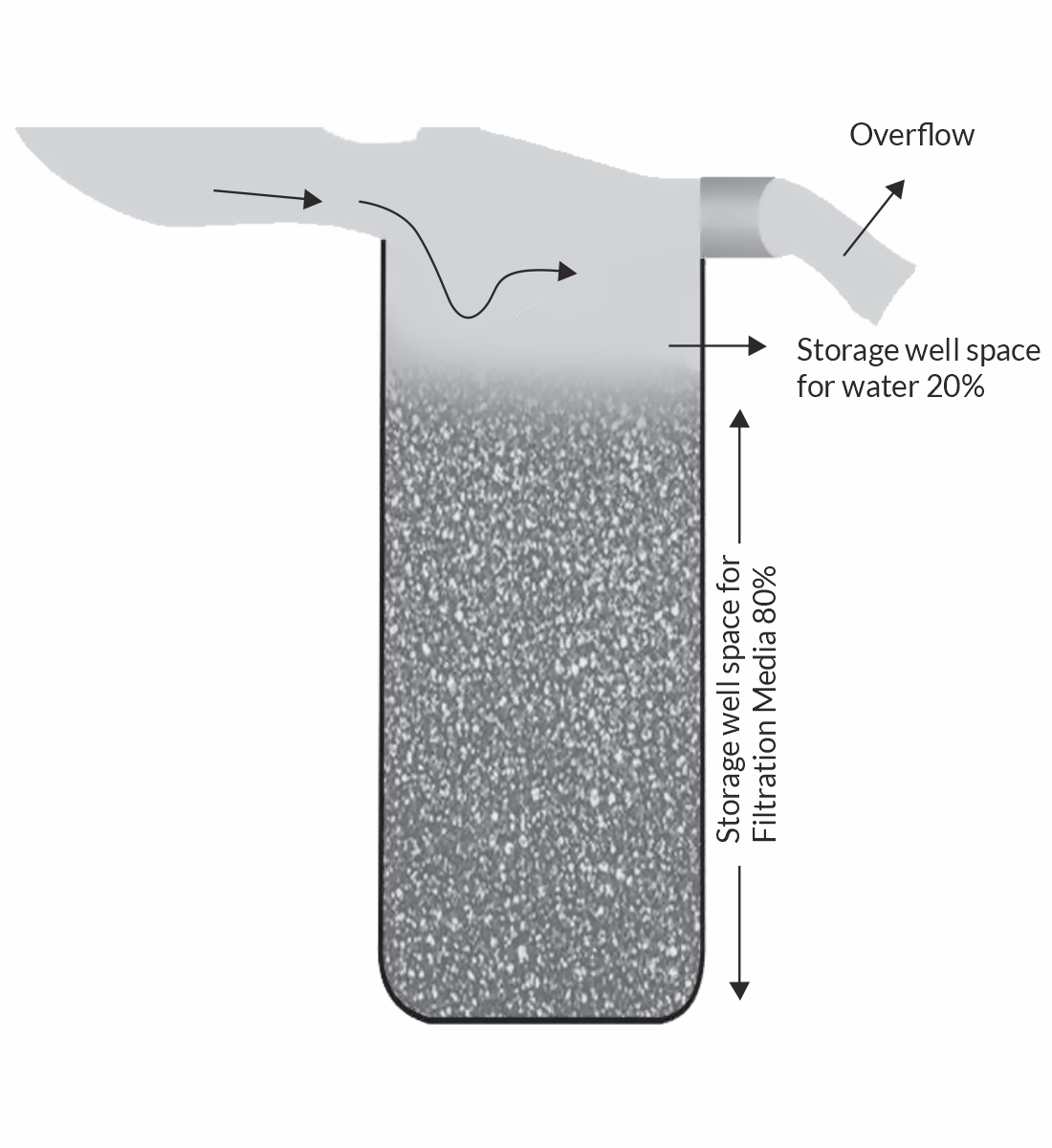

3- In FLRWHS ‘V’ wire technology, 80% of the space is earmarked for storing runoff rainwater, allowing the system to hold a large volume of water and exerting additional water pressure to discharge large amounts of water into the deeper layers of the earth’s aquifer.

4- The ‘V’ wire technology in FLRWHS employs electrical conductivity tests to determine the most favourable points for the quick release of rainwater into the deeper layers of permeable strata.

5- The filtration media in the silt trap of the ‘V’ wire technology creates sufficient space, allowing debris to remain at the bottom and clean water to pass through, leading to the injection well.

Conventional Type

1. Conventional technology lacks a silt trap, resulting in the accumulation of silt directly in the recharging well, which can cause various issues.

2. The depth of rainwater recharge is restricted to 3 meters in the conventional method, leading to potential environmental problems such as waterlogging and soil salinity.

3. The conventional system has insufficient space for rainwater accumulation, as only 20% of the well’s volume is designated for this purpose.

4. During the rainy season, the soil particles are usually saturated with moisture up to their water-holding capacity, causing the recharging well to flood and be unable to hold and discharge the surface runoff water.

5. Unlike most conventional systems, the FLRWHS technology overcomes these limitations with its silt trap, deep recharge point, spacious design, self-purifying filtration media, and electrical conductivity test for accurate water release.

V Wire Screen For Slit Trap Unit

Flanged End at Mouth Side

Continuous Slots

The special design gives continuous slot opening across the periphery and length of screen.

Flat Screen at Back side

Non Clogging Slots

V – Shape wire gives Inwardly widening V- Shapes slots. This shape does not give space for any sand particle to get struck inside the slot and hence these screens and non clogging

• Cage type trapezoidal wire wound screen.

• The diameter of the V Wire Screen is 203mm.

• Screen is evenly distributed continuous slot opening of 3mm, so that it has more open are

for minimum turbulance and loss of energy. Percentage of open are is 70%

• The trapezoidal V Shape inwardly widening slots are non clogging so that sediments

have only point contact

• The V Wire Screen is of stainless steel material, grade S.S. 304

• Over all length including flanges – 0.50 meters.

• The end connection is flat-ended screen at one side and the other end is flanged type.

Functioning of the System

The Rain Water is led through a water channel and first reaches the silt trap, which allows for silt to accumulate in the chamber. The overflow water will be led into the injection well through horizontal connected pipe with V wire Filter Unit, which passes through multi layers of Filtration media placed at the top of the injection well. The water is accommodated in a specially designed storage well, which creates water column. This water column within the walls of the injection Well develops a tremendous pressure on the water body resulting in the downward movement of water, accordingly, injecting large quantities of water into the deeper layers of the permeable & impervious earth’s strata through the Non Clogging V-Wire screens attached to the specifically designed percolator pipe, placed to a deeper depth of 60 meters below the ground. The water column and the dual V-Wire Screen allow for the water to reach the dry joints, cracks, weathered zone, and aquifers and recharge the ground water source.

V Wire Screen

Methodology of Injection Well

Request a Quote

Request a Quote

Our Clients